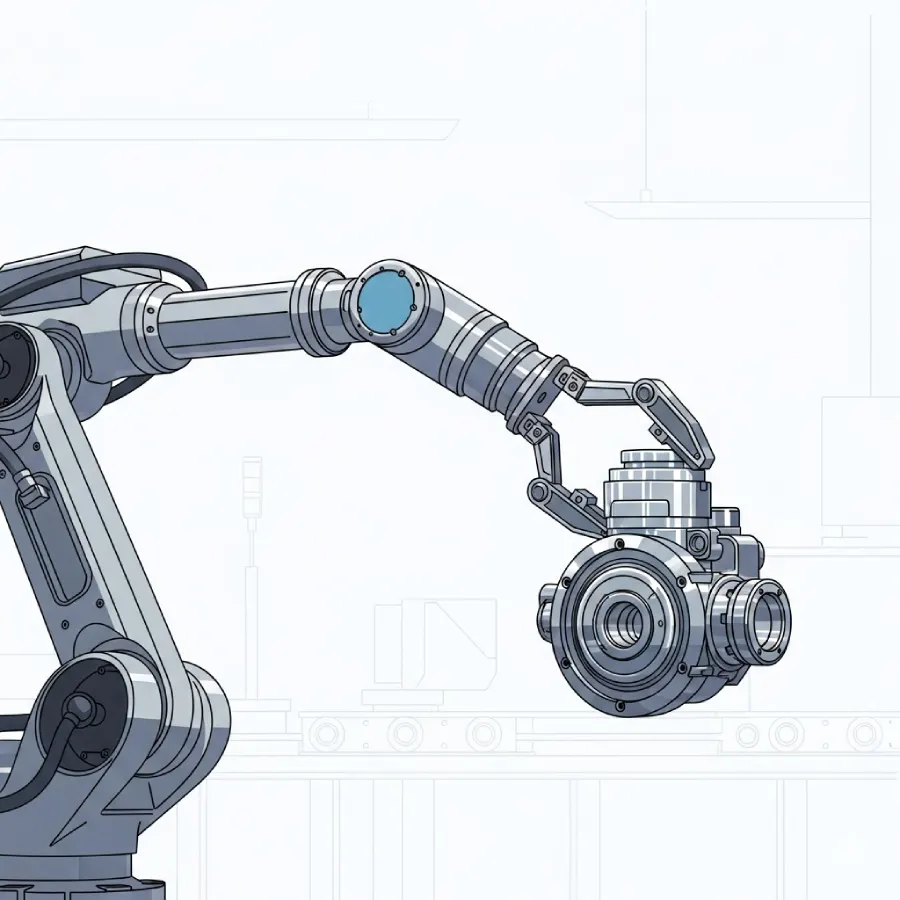

3D scanning is a process that captures the shape and appearance of a physical object or environment in digital form to create a precise 3D model. It is widely used for applications such as reverse engineering, quality inspection, additive manufacturing, and CAD development.

This cutting-edge technology accurately collects data on an object’s shape, size, and texture, enabling seamless integration into digital workflows and transforming industries. Instead of starting from scratch, you can leverage existing excellence with 3D scanning.

A 3D scanner collects detailed data from the surface of physical parts, ensuring high accuracy. In addition, 3D scanning services can help you choose the right scanner for your needs and capture object data quickly and precisely—saving time and effort compared to traditional measurement methods.

3D scanning is an advanced technology that has transformed numerous industries by offering precise and efficient methods to digitize real-world objects and environments.

Reverse engineering is the practice of analyzing and recreating an existing object or design. With the aid of 3D scanning, this process has become faster, more precise, and highly efficient.

3D scanning uses advanced technology to capture the shape, dimensions, and intricate details of a physical object. The collected data is then converted into a 3D CAD model that can be analyzed, modified, or reproduced.

This technique is widely applied across industries such as manufacturing, automotive, aerospace, and product design. It enables companies to examine an object’s design, implement improvements or adjustments, and recreate parts that may no longer be available.

By integrating 3D scanning, reverse engineering becomes a powerful manufacturing tool for understanding, refining, and enhancing products.

Ensuring product quality is a critical stage in manufacturing, and 3D scanning has transformed this process. As an advanced, non-contact technology, it captures an object’s exact shape and dimensions, making quality checks faster and more accurate.

By generating a highly detailed digital model of a product and comparing it with the original CAD design, manufacturers can quickly identify deviations such as incorrect measurements, misaligned components, or surface defects with exceptional precision.

3D scanning works efficiently, even for complex geometries, ensuring products meet the highest quality standards. It minimizes errors, saves time, and has become an indispensable tool in modern production.

Education has been transformed by 3D scanning. Offers interactive learning experiences, especially in fields like engineering

Art and cultural heritage are priceless connections to our history, traditions, and human creativity. Yet preserving these treasures remains a constant challenge, threatened by natural deterioration, environmental conditions, and human impact.

In recent years, 3D scanning has emerged as a groundbreaking tool for documenting, restoring, and sharing artifacts. By producing highly accurate digital replicas, it seamlessly blends tradition with technology, safeguarding the legacy of art and heritage for future generations.