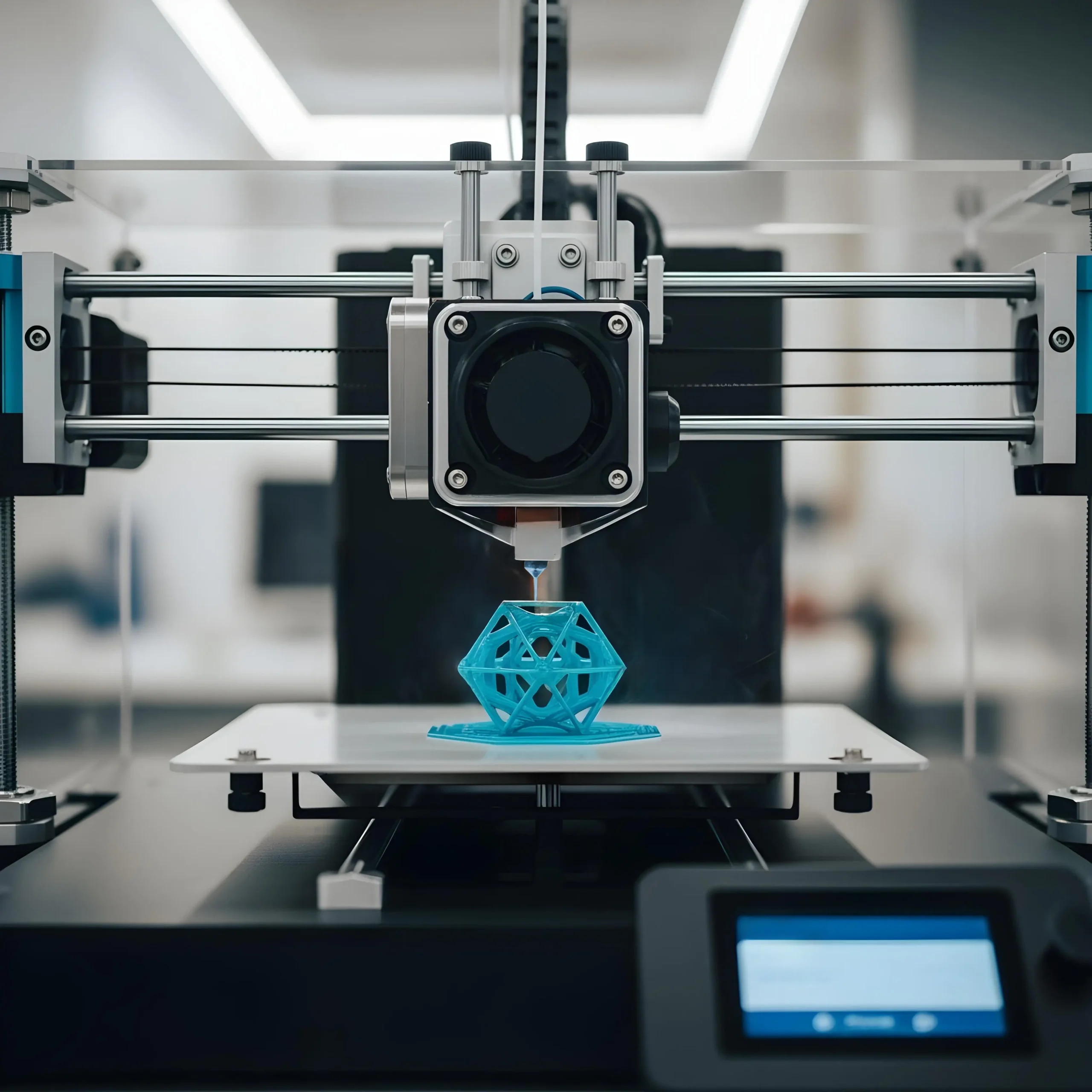

3D printing, also known as additive manufacturing, is a breakthrough technology that creates physical objects directly from digital design files. Using materials such as plastic, resin, or powdered metal, objects are built layer by layer with precision and speed.

This advanced process allows the production of parts with complex shapes and geometries that are difficult or impossible to achieve with traditional manufacturing methods. Whether for prototyping, production, or customization, 3D printing offers endless possibilities.

3D printing enables the creation and production of intricate designs that surpass the limitations of traditional manufacturing methods. Conventional processes impose design constraints that are eliminated with 3D printing.

3D printing can produce components in just a few hours, significantly accelerating the prototyping phase. This rapid turnaround allows each stage to progress more swiftly. In comparison to machining prototypes, 3D printing is both cost-effective and faster, as parts can be completed in hours, facilitating design modifications at a much more efficient pace.

Another benefit is the print-on-demand capability, which requires minimal space for inventory storage, unlike traditional manufacturing methods. This approach conserves space and reduces costs since bulk printing is only necessary when required. The 3D design files are maintained in a virtual library, printed from a 3D model in either CAD or STL format, allowing for easy access and printing as needed. Design edits can be made at minimal costs by modifying individual files, eliminating waste from outdated inventory and the need for new tools.

The primary material used in 3D printing is plastic, although certain metals can also be utilized. Plastics provide advantages due to their lighter weight compared to metal counterparts. This is especially crucial in sectors like automotive and aerospace, where reducing weight can enhance fuel efficiency. Additionally, parts can be manufactured from specialized materials to achieve specific characteristics such as heat resistance, increased strength, or water repellency.

Depending on the complexity and design of a part, 3D printing can produce objects in a matter of hours, which is significantly quicker than traditional moulded or machined components. The time savings offered by 3D printing extend beyond just the manufacturing of the part; the design process can also be expedited by generating STL or CAD files quickly.

3D printing uses computer-aided design (CAD) to create three-dimensional objects through

a layered method. It begins with creating graphic models of the objects to be printed. These

models are often designed with CAD software. Import the files to the 3D printer, and then the

printer completes the work. Based on different working principles, 3D printing technology can

be divided into the following three types:

FDM technology heats and melts filamentous hot-melt material. The computer controls a three-dimensional nozzle that selectively coats the material on the worktable according to the cross-sectional profile. The material forms a layer after cooling quickly. Once one layer is complete, the machine table lowers by the thickness of that layer. It then forms the next layer, repeating this process until the entire solid shape is finished.

This technology spreads a layer of powder material on the upper surface of the molded part. The powder is heated to just below its sintering point. The control system directs a laser beam onto the powder layer according to the layer's cross-sectional profile. After scanning, the powder's temperature increases to the melting point, allowing it to sinter and bond with the molded part below. Once one layer is complete, the workbench lowers by the thickness of that layer. The spreading roller then spreads a new layer of uniform and dense powder and sinters this section until the entire model is finished.

The liquid tank is filled with photosensitive resin. This resin cures quickly under the ultraviolet laser beam emitted by the laser. SLA uses a different laser than SLS; it uses ultraviolet, while SLS uses infrared. At the start, the lifting worktable is below the liquid level, exactly one section thick. The lens focuses the laser beam to scan the cross-sectional profile along the liquid surface according to the machine instructions. The resin in the scanning area quickly solidifies to form a cross-section and creates a layer of plastic. Then, the workbench lowers by the layer's thickness, and the next layer is cured. These layers stack to form a three-dimensional object.