CNC laser cutting is often the first step in 2D sheet metal fabrication. It offers a faster turnaround compared to punching, making it especially efficient for short production runs. In addition, laser cutting provides a higher level of precision and consistency than conventional mechanical cutting methods.

The process produces clean, accurate edges that meet strict tolerances. It is a flexible and versatile manufacturing solution, particularly suited for fabricating intricate shapes that require smooth, distortion-free finishes.

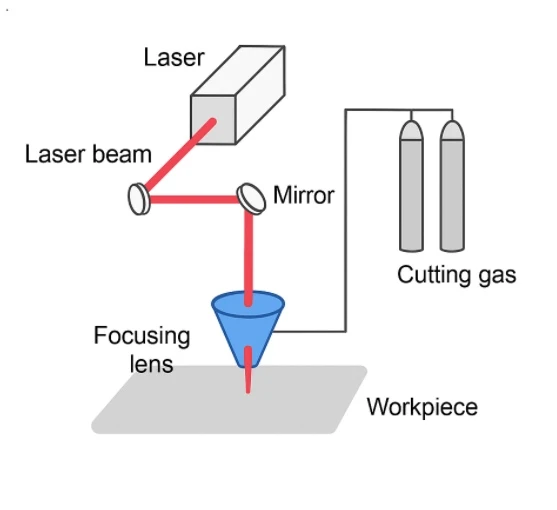

Laser cutting machines focus a high-powered laser beam onto the surface of the material, converting light energy into intense heat. This concentrated heat melts or vaporizes the material, creating a fine cutting line. The laser head moves according to the programmed path, enabling the machine to cut complex shapes with precision.

Best suited for non-metallic materials such as plastics, wood, acrylic, textiles, and certain thin metals.

Ideal for applications requiring high energy density, such as marking, engraving, and specialized cutting of metals and ceramics.

The most versatile and widely used technology for sheet metal cutting. Fiber lasers provide faster speeds, lower maintenance, and higher energy efficiency when cutting steel, aluminum, stainless steel, copper, and brass.

Delivers burr-free, distortion-free cuts.

Perfect for short runs as well as mass production.

Cuts metals, plastics, composites, wood, and more.

Narrow kerf width means optimal use of raw material.